About dye sublimation and how it works

What is dye sublimation?

In short, dye sublimation is a modern digital printing technology which enables the reproduction of high quality images on common everyday items such as ceramic mugs, plates, name tags and awards. We’ll explain the process for you and all the factors that depend on success.

Firstly, the artwork and design is created.

The design is created using a graphics program such as CorelDraw or Photoshop. By using your own photos or artwork combined with the many font options available in these programs, the possibilities are endless.

Then we print the design.

The design is then sent to a sublimation printer that is specially designed for sublimation ink. The printer then prints the design onto heat resistant paper.

Finally, the design is transferred to the item.

The paper is then taped to the item to be sublimated. The item is then placed in a heat press at a temperature ranging from 300 – 400 degrees C depending on the type of item.

The factors that depend on success

There are many factors to take into account with the dye sublimation process. All these factors combined can be the difference between success and failure. Not only does it depend on the person doing the dye sublimation. It also depends on the customer being well informed. We’ll outline the most important factors.

Firstly, of major importance is image quality

Unfortunately some people are under the impression that just any image will work. But to achieve any satisfactory results the image needs to be a high resolution. At least 1MB is required to achieve satisfactory results. We have even been sent images as low as 16KB. Even with the help of photo editing software, images of this size simply can’t be improved on. They will be fuzzy when resized for printing. Photo editing software can do many things but when it comes to low resolution images we can’t be magicians!

Getting the temperature and time right is very important

Time and temperature play a big part in successful dye sublimation. Some items need to be ‘baked’ at a moderate temperature while other items require a higher temperature. The length of time that an item is left in the heat press is also an important factor.

Some items only need a very short amount of time while others may need longer. If an item is ‘baked’ too long and too hot the paper get’s a ‘burnt’ look which in turn will spoil the finished result. A low temperature and short ‘bake’ time can result in uneven printing due to the heat not being distributed to the extremities.

Dye sublimation requires a white surface for best results.

As many of us are probably unaware, a printer cannot print white ink. Mostly printing is done on white paper. Therefore, few of us have stopped to consider the fact that the printer isn’t printing in the white areas.

When the design is transferred to the item the white areas are ‘open’. For example, if the image was printed on a black item the area that should be white would be left black. The same would happen if sublimating onto clear glass. Therefore, if sublimation is to be done on an item that is not white it is important to take this into consideration.

Dye sublimation doesn’t work on mugs and things you buy from the store

For an item to be sublimatable it requires a special invisible polymer coating. The reason for this is because as the ink heats it turns into a gas that melts and blends into the coating to create a permanent image that will not wash off. Without this coating, nothing will happen. Therefore, as a result you end up with the item looking exactly the same as it did before it went in the heat press.

Sublimatable products can only be purchased from specialist suppliers.

We source a wide range of sublimatable items from suppliers like Tilt NZ, Carter NZ and GJS in Australia. If we do not have what you want on our website just ask and we will buy it in.

If you purchase an item from these suppliers you will need to provide proof that it is a sublimatable item. We cannot tell if it is sublimatable just by looking at it.

In addition to that, our equipment might not have the capacity for the item you have in mind. Therefore, to avoid confusion and disappointment, it is best to let us buy it and supply it. Otherwise we will have to add an additional sublimation cost. The price of sublimation is included with the products we sell.

In conclusion – there’s much more to dye sublimation than meets the eye.

Dye sublimation is not a DIY project. You cannot just use an ordinary printer or standard inks and paper. it requires specialised equipment built specifically for dye sublimation. With our specialised equipment, we can create beautiful designs on mugs, beer glasses, keyrings, name tags and many other items. We can also create an award with a sublimated aluminium plate with a personalised image & text to commemorate the event.

You can email us your favourite pictures or logos and we will design to order. Don’t have a picture that quite suits your fancy? Click here to browse thousands of lovely high quality free images on pixabay

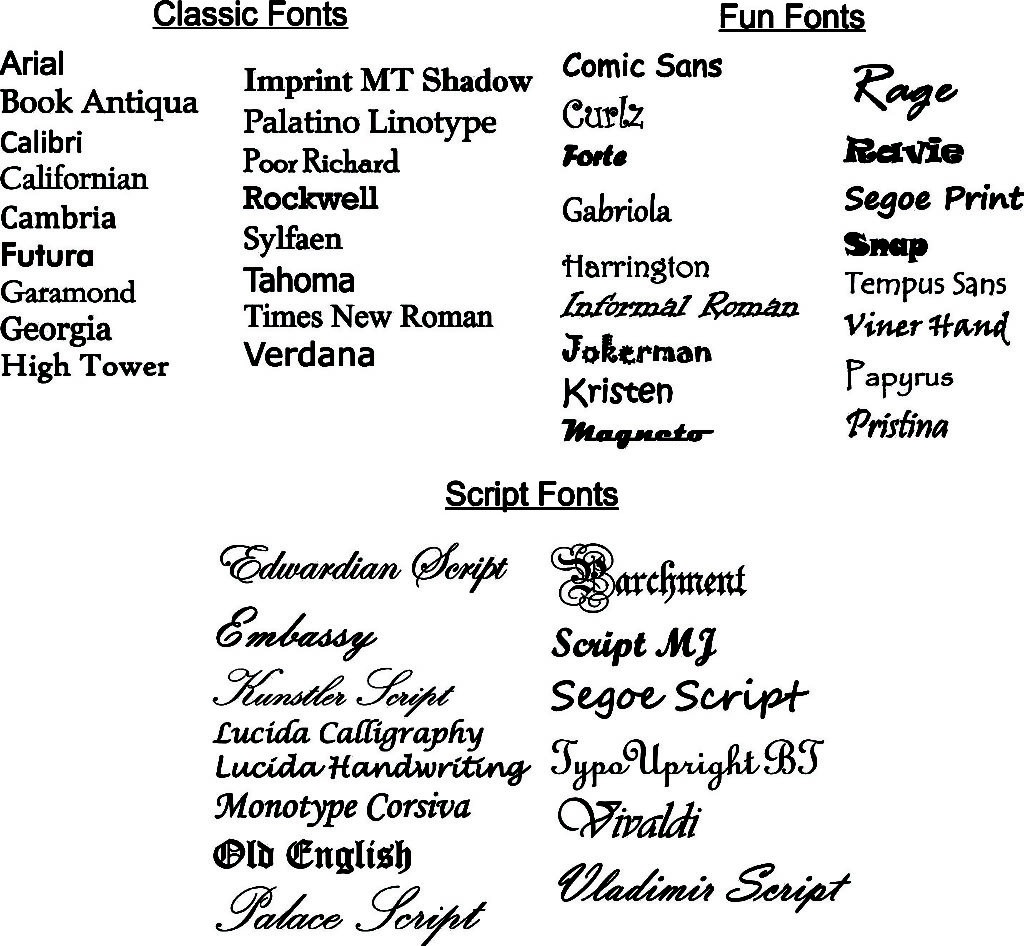

Sublimation Font Options

Here are some of the many fonts available in our CorelDraw software. Our software enables us to create a life like preview to email to you before we proceed with the dye sublimation process. Therefore we can make sure we get everything right and you can rest assured that what you see is what you will get.